Tailor-made Solutions

Benefit from our experience with customized solutions designed to meet your specific requirements.

Complex Tasks

We solve challenges that cannot be addressed with simple solutions

High Precision

Even the smallest production errors are

reliably detected

Seamless Integration

Easy integration with third-party applications and industry interfaces

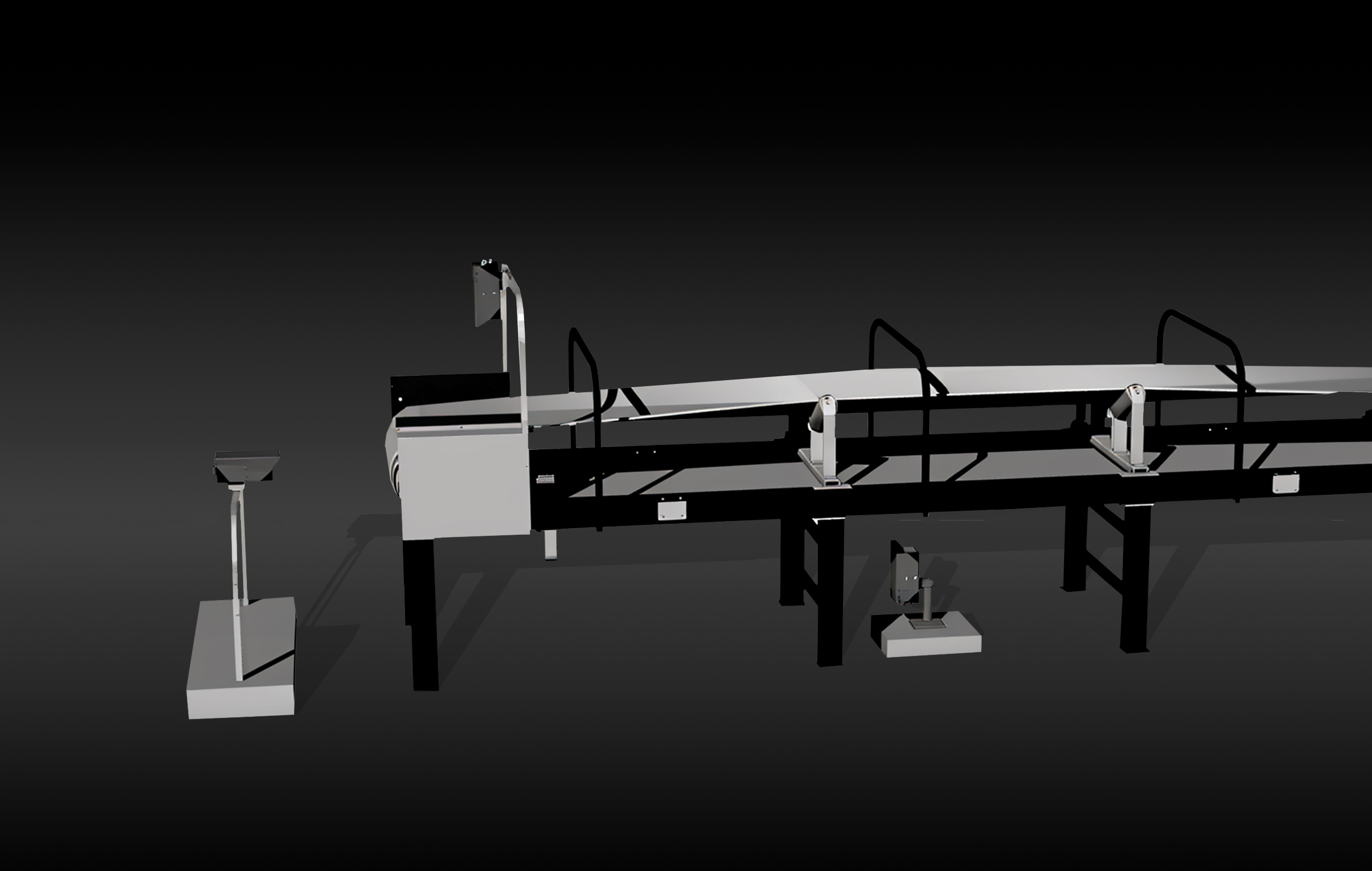

nBelt

The AI-supported conveyor belt inspection detects wear such as cracks, cuts or breaks in real time and enables predictable maintenance to avoid unexpected downtime.

Thanks to its open architecture and support for industry standards, the system can be easily integrated into existing lines.

Flexible, fast and adaptable – with speeds of up to 15 m/s and support for different belt types and colors, the solution adapts perfectly to your requirements.

nWood

The Wahtari nWood solution revolutionizes log inspection by analyzing various quality characteristics with precision and efficiency—both as a standalone system and inline in production. Deviations are detected, signaled, and documented in real time.

Powered by AI-driven technology, nWood operates 24/7 under industrial conditions, far more accurately than the human eye. The analysis is performed on the edge, without cloud connectivity, ensuring maximum data security and minimal latency.

With plug-and-play installation and easy one-person operation, the system is very user-friendly.

Whether for barking levels, wood quality, dimensions or volume - nWood adapts flexibly to your requirements, ensuring optimal efficiency in wood processing.

Get in touch with us

Would you like to find out more about our inspection solution? Get in touch with us and one of our experts will get back to you as soon as possible: [email protected]

FFP2 Mask Inspection

Our AI solution ensures highly accurate detection and sorting of defective masks, including material flaws, printing errors, broken bands, or incorrectly positioned metal hooks.

Despite complex conditions—such as unevenly distributed or unsecured masks—the system achieves a detection rate of over 98% with an analysis time of just 25 ms, delivering efficiency unmatched by manual inspection.

Roof Tile Inspection

Our solution reliably detects and sorts defective roof tiles, including cracks, chipping, and discoloration.

Even with diverse models and a lack of standardization, the system delivers precise results that were previously only achievable through human intuition.

With a detection rate exceeding 99% and an analysis time of just 25 ms, it sets new benchmarks in quality control.